Release Date

Sep 15, 2025

Use Case 5

Industry: Defense Industry

Product:

Defense & Automotive (Military Vehicles and Heavy Equipment)

Product

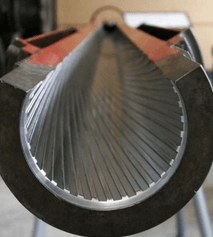

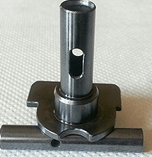

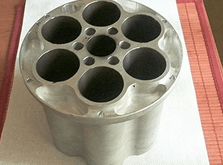

External and Internal Nanoprotection for Hand Grenade Launchers (RBG 40/6 M11)

Advanced anti-friction, anti-wear, and heat-resistant protection designed for barrels and critical weapon components.

- Challenge: Barrel wear and abrasion represent one of the most persistent problems in grenade launchers and other large-caliber weapon systems. Without advanced protective measures, barrels degrade quickly under extreme firing conditions, reducing accuracy, increasing maintenance costs, and requiring frequent replacement.

Problem:

Defense stakeholders faced several recurring issues with hand grenade launchers and similar weapon systems:

Excessive friction and wear accelerated the deterioration of internal barrel surfaces.

Abrasion and heat stress from repeated firing cycles compromised structural integrity.

Lack of effective long-term coatings led to shorter barrel life, more frequent downtime, and higher operational costs.

Conventional surface treatments could not meet the evolving performance requirements of modern combat environments.

Solution

Canyon Engineering provided both the technical materials and professional expertise required to apply advanced nanotechnology-based anti-friction, anti-wear, and heat-resistant coatings.

At the start of the project, user-specific problems and operational requirements were carefully analyzed to ensure tailored solutions.

The nanoprotection technology was then applied to:

Complete internal and external surfaces of hand grenade launchers (RBG 40/6 M11).

Barrels of all calibers, including large-caliber systems, offering versatile applicability across defense platforms.

Results & Benefits

Extended Barrel Life: Testing demonstrated that treated barrels achieved lifespans up to 80% longer than untreated counterparts.

Abrasion Resistance: Internal barrel surfaces maintained structural integrity under high-stress firing cycles, reducing deformation and erosion.

Heat Resistance: Coatings withstood repeated thermal stress, maintaining consistent performance even under heavy use.

Operational Readiness: Reduced need for barrel replacements lowered logistical burdens and ensured greater mission reliability.

Scalable Application: Technology can be adapted to a wide range of calibers, ensuring consistent benefits across diverse defense systems.

✨ Summary

Through the integration of nanotechnology-driven external and internal protections, Canyon Engineering successfully addressed critical challenges in barrel wear, friction, and heat resistance for hand grenade launchers and large-caliber weapons.

By combining technical resources with dedicated expert personnel, the solution not only improved performance but also extended barrel life by up to 80%, delivering substantial operational and cost-saving benefits to the defense industry.