Release Date

Sep 15, 2025

Use Case 2

Industry: Defense Industry

Product: Ultra-thin layers of fullerene nanoparticles of tungsten disulfide

Challenge: Visual inspection of revolver barrels after firing untreated bullets showed significant lead buildup in the grooves

Problem:

Performance of LEAD BULLETS

For this testing, lead bullets LRN 10.2 g, caliber 38 (.3575) were pre-treated.

Bullets were coated with ultra-thin layers of fullerene nanoparticles of tungsten disulfide, without affecting the caliber.

Two revolvers were used:

- Taurus .38 Special, barrel length 4’’

- Ruger .38 Special, barrel length 2’’

Revolvers were previously degreased and properly cleaned. Three series of 5 and 6 rounds were fired from both revolvers, with cleaning of the barrel and chamber after each series.

LEAD BULLETS – RESULTS

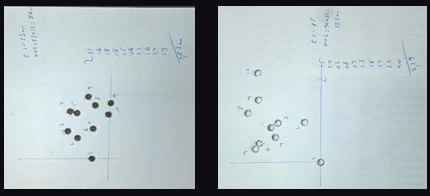

About 80% less lead deposit was observed in bullets coated with tungsten disulfide nanoparticles.

Visual inspection of revolver barrels after firing untreated bullets showed significant lead buildup in the grooves, while this effect was not present with treated bullets.

Untreated Rifle Test Barrel

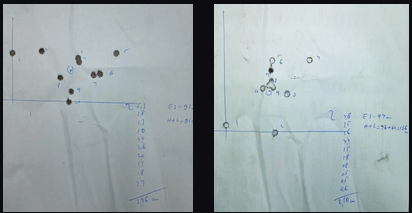

Accuracy was tested at 100 m from the muzzle, using three criteria:

– Es – Maximum distance between two furthest hits on the target

– Rs – Mean radial deviation of the bullet

– H+L – Sum of the maximum horizontal and vertical deviations

Repeated tests showed no significant decrease in bullet velocity. Accuracy of test barrels was fully preserved. Given that treated barrels will experience less wear and deposit buildup, accuracy is expected to remain preserved over a longer period compared to untreated barrels. Testing is ongoing, with expectations of significantly longer barrel life and easier maintenance.