Release Date

March 21, 2025

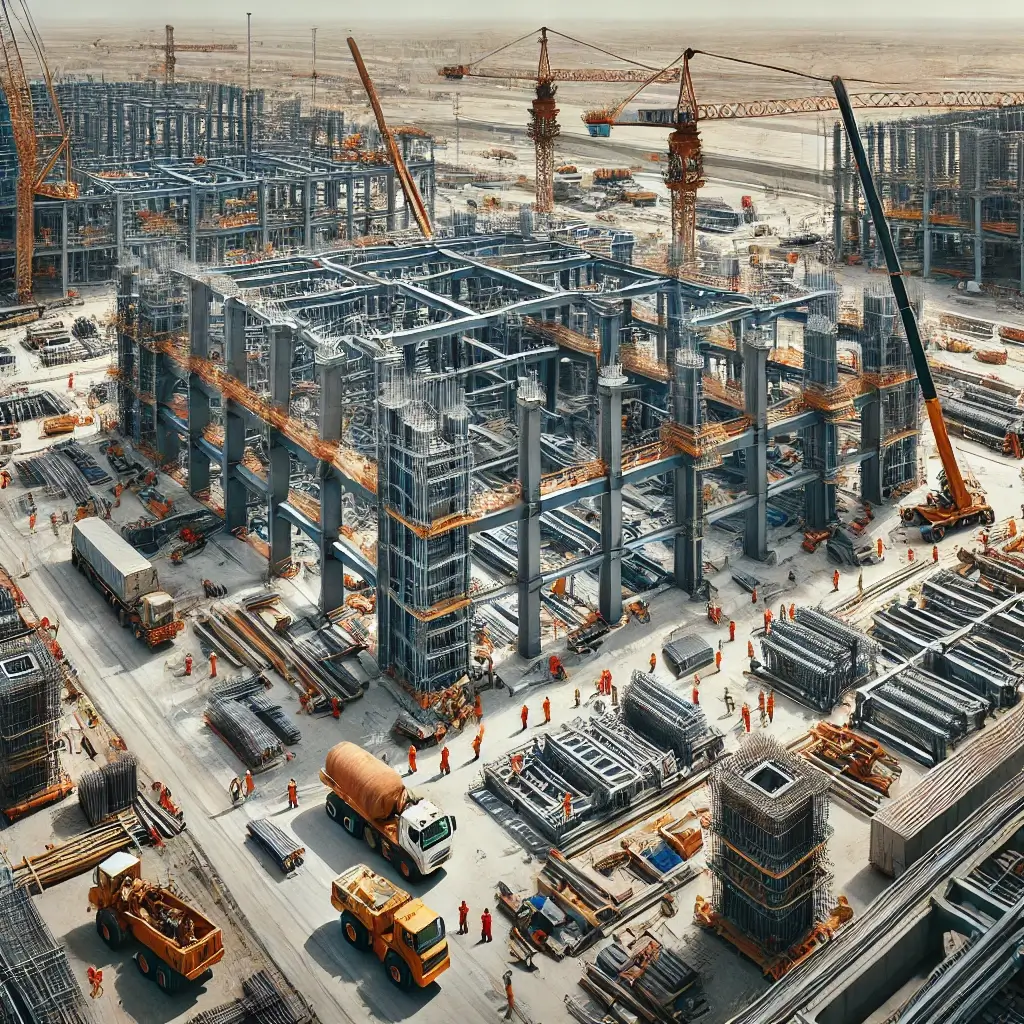

In the rapidly evolving industrial landscape of Saudi Arabia and the broader Gulf Cooperation Council (GCC) region, the significance of high-quality industrial fasteners cannot be overstated.

These essential components serve as the backbone of numerous sectors, ensuring the structural integrity and reliability of everything from towering skyscrapers to intricate machinery. As the region continues its ambitious infrastructural and industrial projects, understanding the nuances of fasteners—their types, applications, and the standards governing them—becomes paramount.

Understanding Industrial Fasteners: A Comprehensive Overview

Industrial fasteners are hardware devices designed to mechanically join or affix two or more objects securely. They are pivotal in ensuring the safety, durability, and functionality of structures and machinery. The primary categories of industrial fasteners include:

Bolts and Screws: Characterized by external threading, these are among the most commonly used fasteners. While bolts typically require a nut to secure them, screws are designed to cut their own threads into materials.

Nuts: Internally threaded fasteners that pair with bolts to clamp components together securely.

Washers: Thin plates with a hole that distribute the load of a threaded fastener, reducing wear and protecting the surface being fastened.

Rivets: Permanent mechanical fasteners that support shear and tensile loads, commonly used in applications where welding isn’t feasible.

Applications of Fasteners in Saudi Arabia and the GCC

The diverse industrial sectors in Saudi Arabia and the GCC heavily rely on fasteners:

Construction and Infrastructure: With mega-projects like NEOM and the Red Sea Project underway, the demand for durable fasteners has surged. These fasteners are integral in assembling steel frameworks, securing facades, and installing essential utilities.

Oil and Gas Industry: As a cornerstone of the region’s economy, this sector requires fasteners that can withstand extreme pressures and corrosive environments, especially in offshore drilling and refinery operations.

Automotive and Aerospace: Precision-engineered fasteners are crucial in these sectors to ensure safety and performance, from vehicle assembly lines to aircraft manufacturing.

Manufacturing and Industrial Machinery: Fasteners play a vital role in assembling machinery, ensuring operational efficiency and safety across various manufacturing processes.

Adherence to International Standards: Ensuring Quality and Safety

In the GCC, adherence to international fastener standards is not just a recommendation but a necessity to ensure safety, compatibility, and performance:

ISO Standards: The International Organization for Standardization provides globally recognized benchmarks for fastener quality and dimensions, ensuring consistency across different manufacturers and applications.

ASTM Standards: The American Society for Testing and Materials offers comprehensive guidelines on material properties and testing methods, ensuring fasteners meet specific mechanical and chemical requirements.

DIN Standards: Originating from Germany, these standards are widely adopted in the region, especially in sectors requiring meticulous precision and reliability.

Market Dynamics and Trends in the GCC Fastener Industry

The industrial fasteners market in the Middle East and Africa was valued at approximately USD 5,909 million in 2022 and is projected to reach USD 9,629 million by 2030, registering a CAGR of 5.3% during the forecast period. Several factors contribute to this growth:Research and Markets

Infrastructure Development: Ambitious projects under initiatives like Saudi Vision 2030 have led to increased demand for construction materials, including high-quality fasteners.

Manufacturing Sector Expansion: The GCC’s focus on diversifying its economy has led to growth in manufacturing industries, subsequently driving the need for industrial fasteners.

Technological Advancements: The integration of advanced materials and coatings in fastener production enhances durability and performance, meeting the evolving needs of various industries.

Selecting the Right Fastener: Key Considerations

Choosing the appropriate fastener is crucial for the success and safety of any project:

Material Compatibility: Ensuring the fastener material is compatible with the joined materials prevents galvanic corrosion and ensures structural integrity.

Environmental Factors: In corrosive environments, such as offshore platforms, selecting fasteners with appropriate coatings or materials like stainless steel is essential.

Mechanical Requirements: Understanding the load-bearing requirements and mechanical stresses helps in selecting fasteners with suitable tensile strengths and properties.

Conclusion

As Saudi Arabia and the GCC continue to embark on transformative projects across various sectors, the role of industrial fasteners becomes increasingly significant. Ensuring that these components meet international standards and are aptly chosen for specific applications is paramount for the safety, efficiency, and longevity of structures and machinery. By staying informed about the types, applications, and standards of fasteners, industry professionals can contribute to the region’s sustainable and robust development.