Release Date

August 23, 2025

In the world of Engineering, Procurement, and Construction (EPC) projects, success is measured not only by how structures rise but also by how seamlessly the supply chain performs behind the scenes.

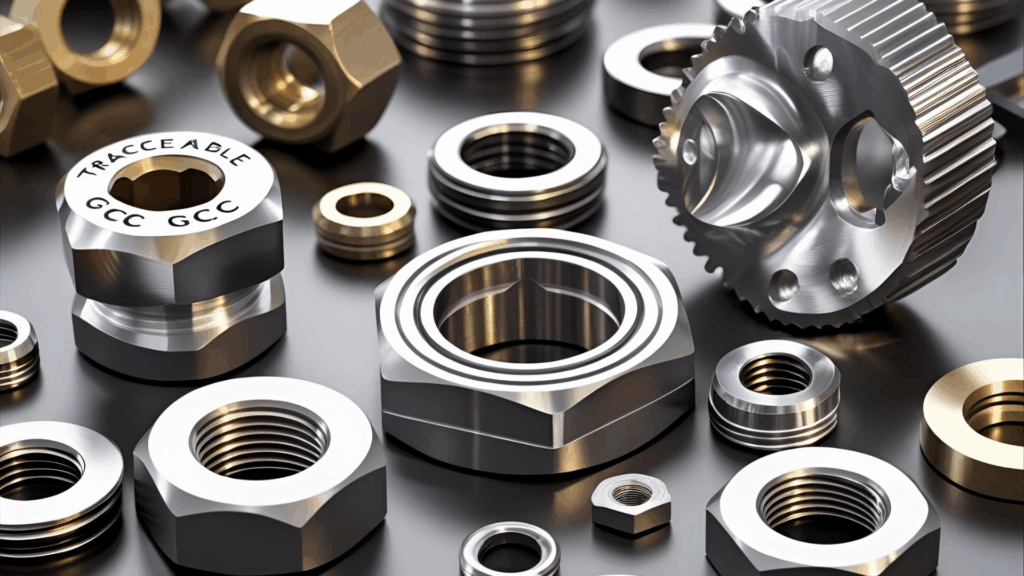

Amid billion-dollar contracts, high-pressure timelines, and strict compliance checks, even the smallest component—the humble fastener—can determine whether a project proceeds on schedule or stalls.

Enter QR-coded traceable fasteners—a quiet revolution in procurement that bridges compliance, efficiency, and accountability.

Companies like Canyon Engineering are leading this transformation in the GCC by offering fasteners equipped with digital traceability that begins at the factory floor and extends to the final installation in the field.

📌 Why Traceability is No Longer Optional in EPC Projects

For mega-projects under Saudi Arabia’s Vision 2030 and across the wider GCC, compliance has become as important as construction itself.

EPC contracts today carry heavy penalties for material non-conformance or documentation gaps. A single uncertified fastener can trigger:

🚫 Audit rejections by regulators or project owners

⏳ Project delays due to additional inspections or re-testing

💸 Financial penalties for suppliers and contractors

🏗️ Structural risks, especially in oil & gas, coastal, or logistics infrastructure

This is why traceability has evolved into a baseline requirement for EPC sourcing.

In fact, according to industry reports, over 65% of EPC firms in the GCC now mandate batch traceability for all structural and high-tensile fasteners in procurement contracts (2025 EPC Procurement Trends Report).

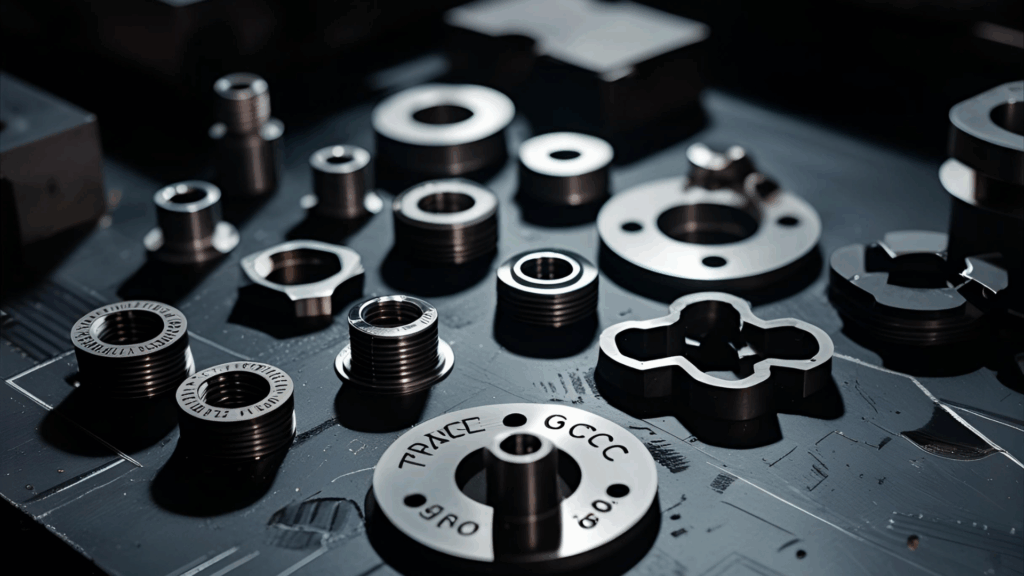

🔍 How QR-Coded Fasteners Transform Procurement Transparency

Traditional fastener procurement often relied on printed certificates and manual logging—a process prone to human error and misplacement.

Canyon Engineering has redefined this model with a digitally integrated traceability ecosystem:

Key Features of QR-Coded Traceability:

✅ Batch Number Linkage – Every fastener is tied to a unique batch number for instant compliance validation.

✅ Digital MTCs (Mill Test Certificates) – Quality, tensile strength, and material composition reports are accessible through secure QR-code scans.

✅ On-Site Verification – EPC engineers can confirm compliance instantly on-site, reducing audit delays.

✅ IMS Integration – Canyon’s Integrated Management System (IMS) syncs fastener deliveries with project Bill of Materials (BOMs), ensuring accuracy and reducing rework.

This end-to-end transparency means project managers no longer chase paperwork; instead, documentation comes built into the fastener itself.

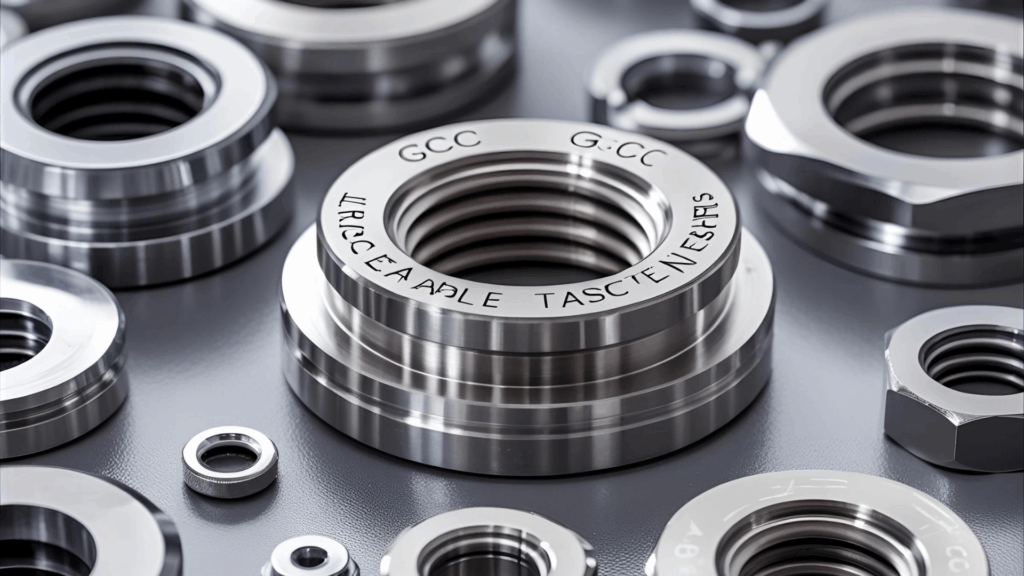

⚙️ EPC Confidence Through Certified Material Traceability

Confidence in EPC isn’t just about supplying a bolt—it’s about ensuring that bolt meets Aramco, ISO, ASTM, and SABIC standards every time. Traceable fasteners from Canyon Engineering offer compliance-ready procurement with:

📊 Salt-spray and fatigue test results linked to each QR code

📑 Digital archives for quick retrieval during audits

🔒 Tamper-proof documentation, preventing mislabeling or counterfeiting risks

🌍 Cross-GCC applicability, as documentation meets procurement requirements across Saudi Arabia, UAE, and Oman

This approach reduces approval timelines significantly.

In fact, EPC contractors using digital traceable procurement report up to 25% faster clearance during audit checks compared to traditional documentation systems (2025 GCC Construction Compliance Survey).

🏗️ Real-World Impact: From Factory to Field

The benefits of QR-coded fasteners go beyond compliance—they directly impact project timelines and profitability.

Case Scenarios:

Oil & Gas Facilities: With heat-resistant, high-tensile fasteners traceable to test results, EPC firms reduce the risk of installation delays in refinery shutdowns.

Coastal Infrastructure: For desalination plants and jetties, coated bolts linked to corrosion-cycle certificates simplify marine regulatory approvals.

Smart City Builds: Complex mega-projects rely on multi-vendor supply chains. QR-coded fasteners consolidate documentation into a single scan, keeping procurement lean and transparent.

By eliminating bottlenecks in inspections and approvals, Canyon Engineering’s traceable fasteners GCC solution enables smoother handovers and more predictable project execution.

📈 The 2025 Outlook: Procurement Transparency as a Standard

With giga-projects accelerating across the region, procurement transparency is no longer a value-add; it’s an expectation.

According to GCC industry forecasts, traceable procurement systems will cover 80% of EPC fastener contracts by 2027, making them as essential as tensile grades themselves.

As a digital MTC fastener supplier and compliance-focused partner, Canyon Engineering is positioned at the forefront of this trend—merging material science with digital innovation.

🔚 Conclusion: The Fastener That Passed

In the complex puzzle of EPC procurement, every fastener must not only hold structures together but also withstand the weight of documentation, compliance, and traceability.

By embracing QR-coded packaging, batch traceability, and digital certifications, Canyon Engineering ensures that its products are audit-ready, field-ready, and future-ready.

For contractors and EPC firms navigating the challenges of certified material traceability in Saudi Arabia and the GCC.

One truth stands clear: in an industry where delays cost millions, the fastener that passes is the fastener you can trace.