Release Date

May 09, 2025

In the dynamic landscape of industrial development, particularly within the Gulf Cooperation Council (GCC) region, the selection of appropriate fasteners is pivotal. With Saudi Arabia’s Vision 2030 propelling extensive infrastructure projects, the demand for reliable and high-performance fasteners has surged.

This blog aims to provide a comprehensive guide to identifying the right fastener for various industrial applications, ensuring structural integrity and longevity.

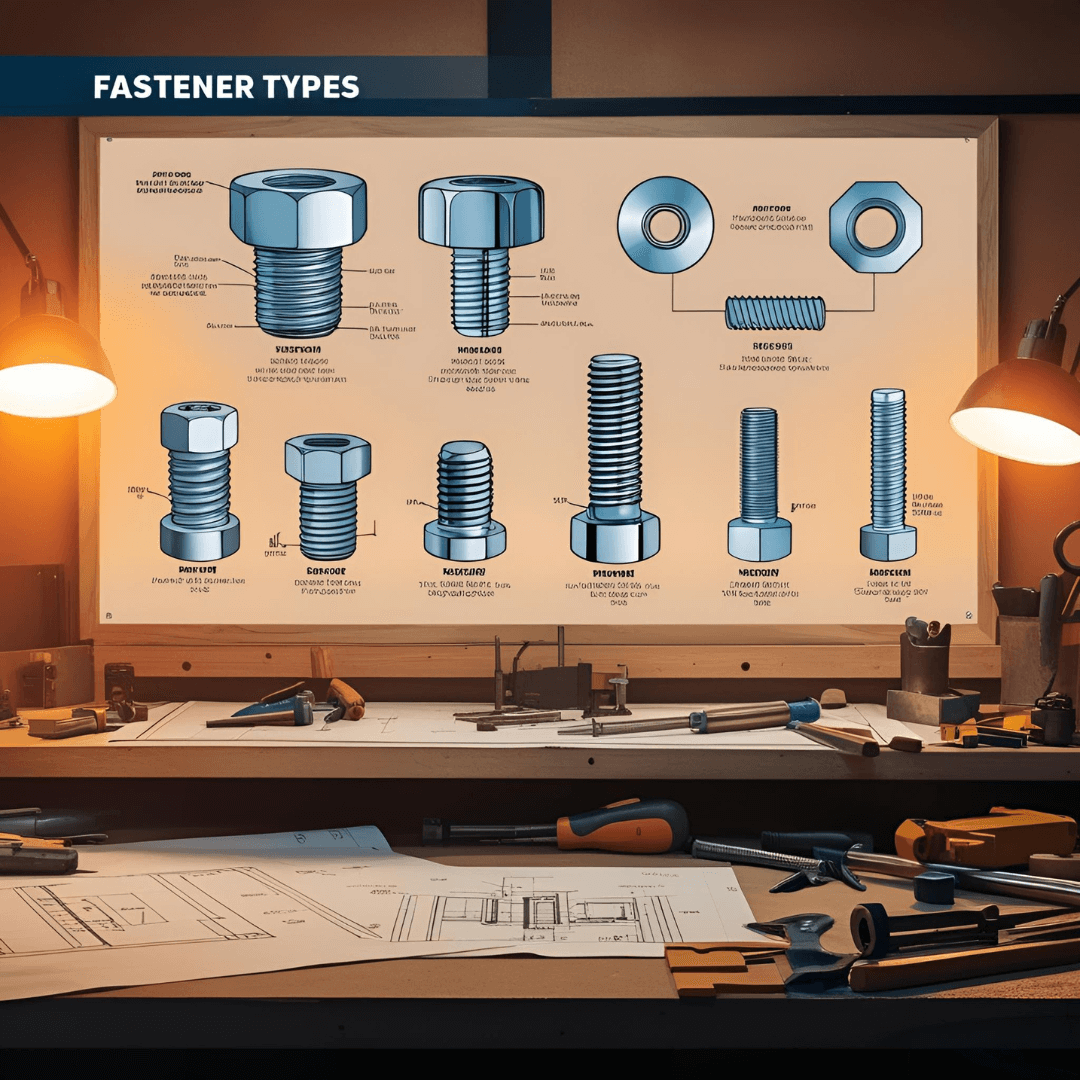

Understanding Fastener Fundamentals

Fasteners are hardware devices that mechanically join or affix two or more objects together. They come in various forms, including bolts, screws, nuts, and washers, each designed for specific applications and load requirements.

In industrial settings, the choice of fastener impacts not only the assembly process but also the performance and safety of the final product.

Key Considerations for Fastener Selection

1. Application Requirements

Understanding the specific requirements of your application is the first step. Consider factors such as load types (tensile, shear), environmental conditions (corrosive, high-temperature), and assembly methods. For instance, in offshore oil rigs, fasteners must withstand corrosive saltwater environments, necessitating materials like stainless steel or coated alloys.

2. Material Compatibility

Selecting a fastener material compatible with the materials being joined prevents galvanic corrosion and ensures joint integrity. Common materials include:

Carbon Steel: Widely used due to its strength and cost-effectiveness.

Stainless Steel: Offers excellent corrosion resistance, ideal for marine and chemical applications.

Alloy Steel: Provides higher strength, suitable for high-stress applications.Meigesi

3. Mechanical Strength Ratings

Fasteners are graded based on their mechanical properties. For example:

Grade 5: Medium strength, used in automotive applications.

Grade 8: High strength, suitable for heavy machinery.

Understanding these ratings ensures the fastener can handle the operational stresses without failure.

4. Compliance with Standards

Adherence to international standards like ASTM, ISO, and DIN guarantees quality and compatibility. In Saudi Arabia, Aramco-certified fasteners are preferred for their compliance with stringent quality benchmarks, ensuring safety and reliability in critical applications.

Fasteners in EPC Projects

Engineering, Procurement, and Construction (EPC) projects demand fasteners that can endure diverse challenges. High-tensile bolts are often employed for their ability to withstand substantial loads. In the GCC, the fastener market is witnessing a shift towards products that offer enhanced performance and durability, aligning with the region’s ambitious infrastructure goals.

The GCC Fastener Market Landscape

The industrial fasteners market in the GCC is experiencing robust growth, driven by large-scale projects and a focus on local manufacturing. Saudi Arabia, in particular, is investing heavily in infrastructure, with the fastener market expected to align with this upward trajectory. Companies are increasingly seeking Aramco-certified fasteners suppliers in KSA to ensure compliance with national standards and project specifications.

Canyon Engineering: Your Trusted Fastener Partner

As a leading Aramco-certified fasteners supplier in Saudi Arabia, Canyon Engineering offers a comprehensive range of high-tensile fasteners tailored to meet the demands of various industrial applications. Our products are designed to withstand the rigors of heavy-duty operations, ensuring safety and longevity.

Our Offerings Include:

High-Tensile Bolts: Engineered for maximum strength and durability.

Heavy-Duty Nuts & Washers: Designed to complement our bolt offerings, ensuring secure assemblies.

Custom Fastener Solutions: Tailored to meet specific project requirements, ensuring optimal performance.

By choosing Canyon Engineering, you’re partnering with a supplier committed to quality, compliance, and customer satisfaction.

Conclusion

Selecting the right fastener is a critical decision that impacts the safety, performance, and longevity of industrial applications. By understanding application requirements, material compatibility, mechanical strength ratings, and compliance standards, you can make informed choices that align with your project’s needs.

In the evolving landscape of the GCC’s industrial sector, partnering with a trusted supplier like Canyon Engineering ensures access to high-quality, Aramco-certified fasteners that meet the region’s ambitious infrastructure goals.