Quality Standards

At Canyon Engineering, Quality is More than a Standard, it’s the Foundation of Our Commitment to Excellence

Unmatched Reliability and Performance

Our Fasteners are meticulously designed, manufactured, and tested to comply with globally recognized standards, ensuring unmatched reliability and performance across diverse applications

Our Quality Standards

Here are a few standards we adhere to for our fasteners manufacturing.

ASTM Standard

The American Society for Testing and Materials (ASTM) sets comprehensive standards for fastener quality, specifying material composition, dimensional accuracy, mechanical strength, and metallurgical properties to ensure reliable performance in critical applications. At Canyon Engineering, our ASTM-compliant bolts, screws, washers, rivets, and threaded fasteners undergo rigorous testing to guarantee optimal performance under extreme conditions like high pressures, fluctuating temperatures, and corrosive environments, delivering the strength and resilience demanded in construction, manufacturing, and specialized equipment.

ISO Standard

Introduced by the International Organization for Standardization (ISO) in 1947, ISO metric screw threads established a global standard fostering interoperability and uniformity across industries, becoming the backbone of modern engineering. Our ISO-certified fasteners, including screws and bolts like M6 sizes, are precisely engineered to ensure seamless integration across international supply chains, offering exceptional reliability in applications from aerospace to consumer goods—highlighting Canyon Engineering’s commitment to global quality standards.

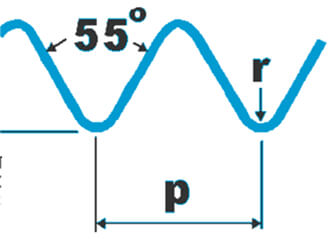

British Standard Whitworth

Developed by Sir Joseph Whitworth in 1841, the British Standard Whitworth (BSW) was the first standardized thread form with a 55-degree flank angle and rounded roots and crests, paving the way for uniform engineering threads. Although largely replaced by Unified and Metric thread forms, BSW remains vital for legacy systems and specific industrial applications; Canyon Engineering manufactures BSW-compliant fasteners per BS 84 – 2007, ensuring compatibility for clients needing reliable solutions in legacy equipment, historic restorations, or specialized machinery.

SAE Standard

The Society of Automotive Engineers (SAE) classifies bolts by grades ranging from 2 to 8, focusing on material strength and manufacturing methods; higher grades indicate superior strength and performance essential for demanding mechanical applications like heavy-duty machinery, automotive components, and industrial equipment. Canyon Engineering’s SAE-compliant bolts are designed to withstand the most challenging conditions—our grade 2 bolts serve general-purpose needs, while grade 8 bolts are ideal for high-stress environments, delivering exceptional tensile strength, durability, and performance; additionally, our Allen bolts exceed typical strength capacities, providing superior fastening solutions for specialized requirements.

DIN Standard

The Deutsches Institut für Normung (DIN) represents the pinnacle of German engineering and precision, offering standards that have shaped global manufacturing practices for decades; while many DIN standards have been harmonized with ISO or EN specifications, they remain critical for products without updated international equivalents. Canyon Engineering’s adherence to DIN standards ensures exceptional quality and reliability for industries requiring high-performance fasteners; our DIN-compliant bolts, screws, and washers embody the precision and craftsmanship defining German engineering, serving applications from heavy machinery to specialized equipment.

JIS Standard

The Japanese Industrial Standards (JIS), coordinated by the Japanese Industrial Standards Committee (JISC), reflect Japan’s innovative manufacturing approach, offering fasteners that meet the precise needs of compact, high-performance designs in industries such as electronics, automotive, and precision machinery where space-saving and lightweight components are essential. Canyon Engineering’s JIS-compliant fasteners feature unique head sizes and compact designs, facilitating efficient assembly and enhanced performance; by aligning with JIS standards, we cater to industries requiring smaller, lighter, yet equally durable fastening solutions.