Release Date

May 03, 2025

The Future of Surface Protection in the GCC Energy Sector: Featuring Nano Additives by Canyon Engineering

Introduction

As the energy sector in the Gulf Cooperation Council (GCC) region accelerates toward megaprojects under Saudi Vision 2030, infrastructure resilience and asset longevity are becoming critical imperatives. The harsh environmental conditions—extreme heat, sandstorms, saline humidity, and chemical exposure—demand surface protection systems that can outperform traditional coatings. Nano Additives, a cutting-edge product developed by Canyon Engineering, emerges as a game-changing solution tailored for such challenges.

As an Independent Development Co. for Nano Solutions, Canyon Engineering is paving the way for nanotechnology adoption in oil & gas, utilities, and heavy industry by introducing advanced coating systems engineered for performance, protection, and sustainability.

🧪 What is Nano Additives?

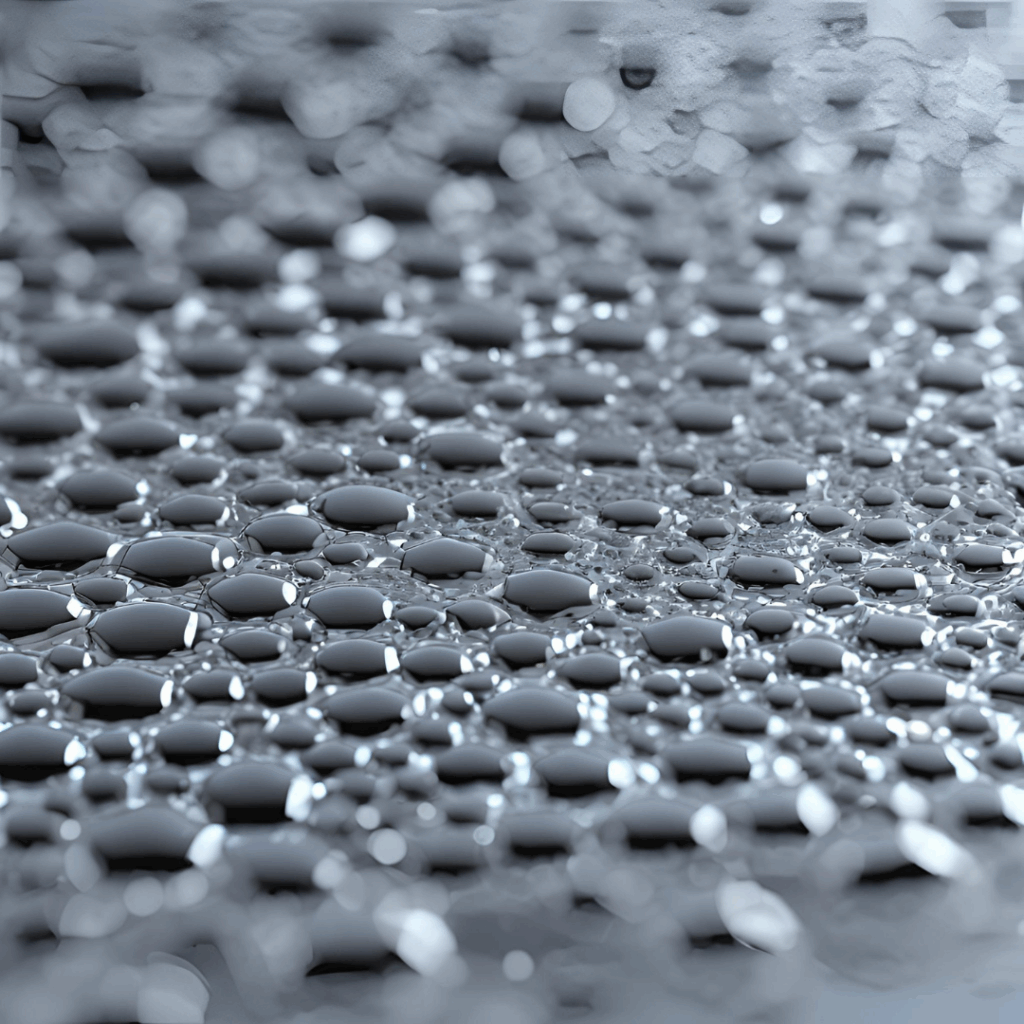

Nano Additives is a protection coating, designed to provide exceptional anti-corrosion and anti-wear properties across high-demand industrial settings. Its foundation lies in advanced nanostructured chemical matrices, offering:

Thermal resistance

High adhesion on metal substrates

Protection against moisture, salt spray, and hydrocarbons

High scratch and abrasion resistance

This system represents a fusion of nano-ceramic particles and polymers to form a resilient barrier—ideal for the demanding conditions in refineries, petrochemical plants, pipelines, and offshore facilities.

🔍 Why Surface Protection Matters in the GCC Energy Sector

GCC countries, especially Saudi Arabia, UAE, and Qatar, are investing billions into energy infrastructure, hydrogen development, and offshore exploration. The Red Sea Project, NEOM, and Aramco’s Jafurah Gas Field are just a few examples requiring next-gen asset protection.

According to a 2025 report by Arabian Industry, corrosion costs the GCC over $80 billion annually. Traditional paint coatings fail to deliver under the intense thermal cycles and saline corrosion. This gap is precisely where Nano Additives excels.

🔬 Nano Science Behind Nano Additives

Nano Additives leverages nanostructured ceramic molecules that:

Interlock with the surface at the microscopic level

Provide low permeability against water and gas diffusion

Maintain performance even under thermal shock and UV degradation

The result is a coating system that extends component life by 3–5x and reduces unplanned maintenance shutdowns by up to 40%.

💡 Key Features & Benefits

| Feature | Benefit |

|---|---|

| High Temperature Resistance | Effective in turbines, boilers, and pipelines |

| Nano-Ceramic Matrix | Superior barrier properties |

| Solvent-Free | Environmentally friendly & low VOC |

| Excellent Adhesion | Reduced peeling, cracking, and reapplication |

| Chemical & Salt Resistance | Ideal for marine, offshore, and refinery use |

🏗 Applications Across Energy Infrastructure

Nano Additives is ideal for:

Oil & Gas Pipelines: Resisting crude oil, hydrogen sulfide, and saltwater exposure.

Heat Exchangers & Furnaces: Withstanding high temperatures and chemical vapors.

Offshore Platforms: Protecting against wave impact, UV rays, and humidity.

Storage Tanks: Shielding metal from corrosive chemicals and sludge.

Aramco Facilities: As an Aramco-certified fasteners supplier KSA, Canyon Engineering complements its fasteners with Nano Additives for complete corrosion-resistant assemblies.

🚛 Logistics & Availability

Based in Al Khobar, Canyon Engineering operates a fully integrated Nano Solutions Lab and Warehousing System, enabling:

Fast-track delivery across Saudi Arabia & GCC

In-stock availability of Nano Additives in various formats (liquid coating, spray application)

Custom solutions for EPC contractors and end-users

🤝 Why Canyon Engineering?

As a trusted Saudi Arabia industrial trading firm, Canyon Engineering is more than a supplier—we are innovation partners for the future of infrastructure protection. With in-house nanotech development, a certified supply chain, and a proven record in GCC megaprojects, we bring:

Technical consultation and product matching

Custom batch production for specific industrial use cases

EPC collaboration models for long-term maintenance savings

🚀 Conclusion

The future of surface protection lies in science-backed, real-world-proven solutions like Nano Additives. For project owners, EPC contractors, and industrial operators in the GCC energy sector, this nano-coating is not just a layer—it’s a shield for operational integrity, safety, and cost control.

Choose Canyon Engineering — your Independent Development Co. for Nano Solutions.

Let’s build smarter, safer, and longer-lasting infrastructure together.