Release Date

May 14, 2025

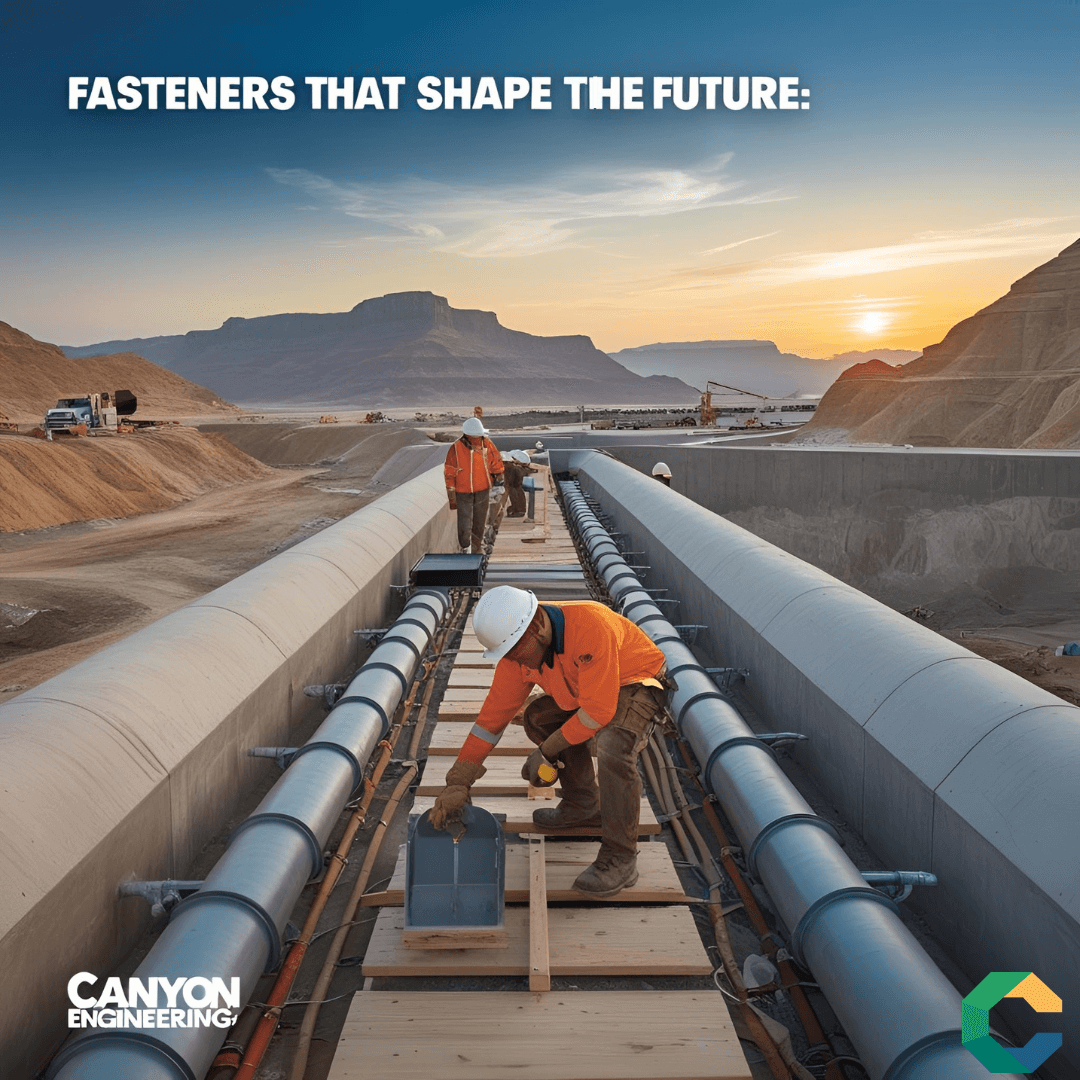

Saudi Arabia’s Vision 2030 is not just a blueprint for economic diversification—it’s a roadmap for reimagining a nation’s infrastructure, sustainability, and global competitiveness. With over SAR 5 trillion ($1.33 trillion USD) allocated to infrastructure and giga-projects across the Kingdom, construction is booming. But while soaring towers and smart cities capture headlines, the success of these projects often hinges on something far less visible—industrial fasteners.

As an Aramco-certified fasteners supplier in KSA, Canyon Engineering plays a critical role in building the structural backbone of Vision 2030. From high-tensile bolts used in tunnels to heavy-duty nuts securing logistics and rail infrastructure, Canyon Engineering’s solutions are at the core of the nation’s most ambitious projects.

🔩 Fasteners: The Hidden Backbone of Modern Infrastructure

In any megaproject—be it NEOM, the Red Sea Project, or the Riyadh Metro—fasteners are the unseen heroes that uphold safety, durability, and performance. These components connect steel beams, anchor bridges, stabilize tunnel linings, and hold together the modular smart buildings shaping tomorrow’s cities.

Given the Gulf region’s exposure to high heat, sandstorms, and corrosive marine air, fasteners in Saudi Arabia must meet extreme performance standards. This is where Canyon Engineering delivers unmatched value: providing ISO, ASTM, and DIN-certified fasteners designed for long-term resilience and precision-engineered to meet EPC project needs.

🏗️ Innovation for Vision 2030: Where Fasteners Matter Most

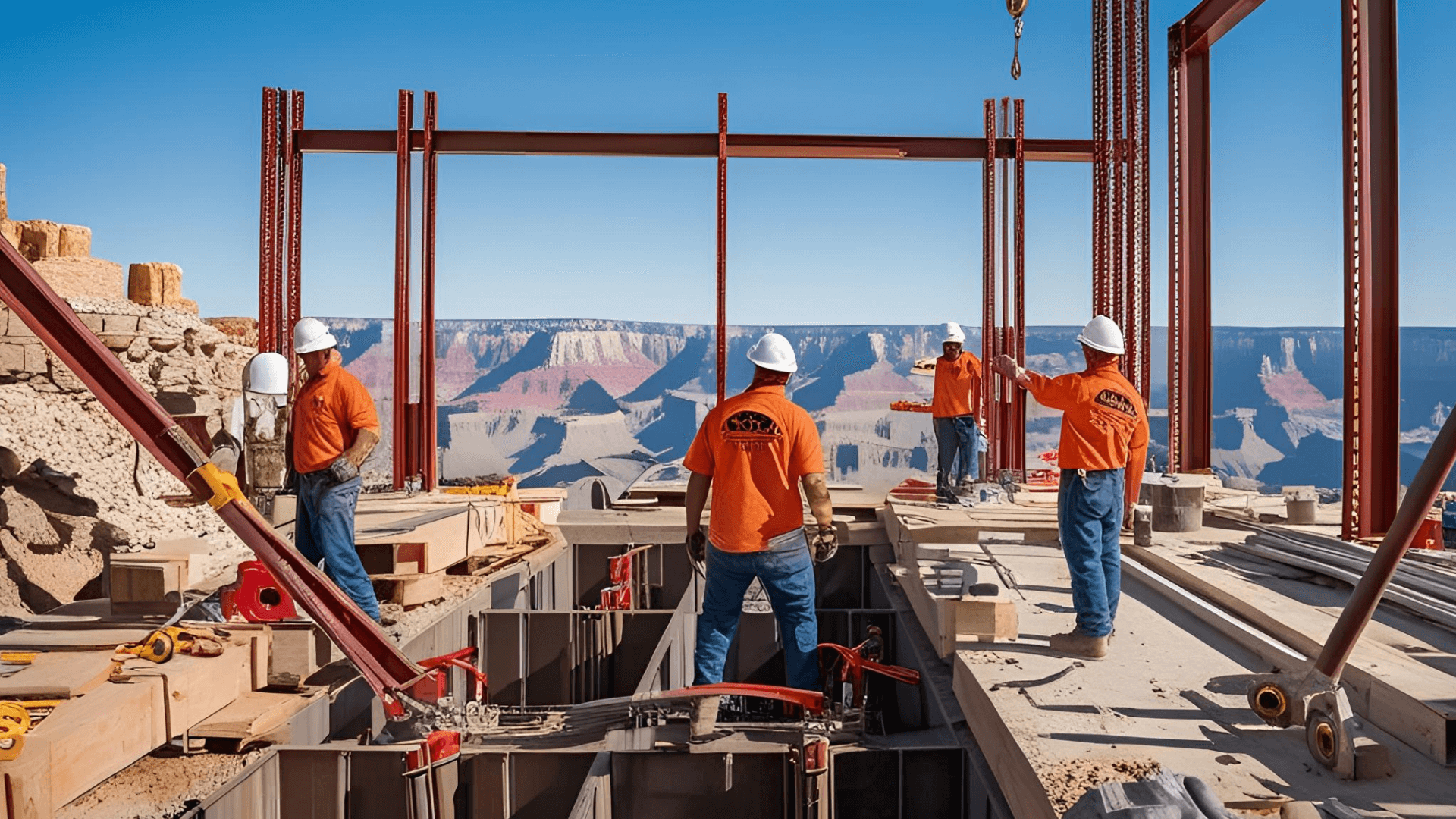

1. Tunnels and Subterranean Infrastructure

Saudi Arabia is investing in high-speed rail and underground mobility projects like the Riyadh Metro and NEOM’s underground services network. These require:

High-tensile bolts for withstanding structural stress

Corrosion-resistant coatings like HDG and PTFE

Precision fasteners to handle seismic activity and soil movement

Canyon Engineering supplies pre-certified fastener kits with full traceability and QA documentation, ensuring quick EPC compliance and safer installations.

2. Logistics and Smart Warehousing

With the rise of logistics mega-hubs like King Salman Park and SPARK, heavy-duty fasteners are essential for steel warehouses, conveyor systems, and modular racking. Canyon Engineering provides:

Heavy-duty bolts and nuts with tensile ratings exceeding 1,200 MPa

Flange bolts and stud bolt kits for load-bearing applications

Inventory support with over 100,000 SKUs stored in Al Khobar for immediate dispatch across the GCC

3. Smart Cities and Urban Mobility

Projects like The Line at NEOM and Diriyah Gate demand sustainable, modular construction. Here, Canyon’s offerings include:

Machine screws, socket screws, and structural anchors

Fasteners with anti-vibration technology

Custom coating solutions for UV, humidity, and salt air resistance

All products comply with Aramco’s material approval protocols, ensuring integration with large-scale energy and urban projects.

✅ The Aramco Advantage: Quality and Compliance

Being an Aramco-certified fasteners supplier in KSA is more than a badge—it’s a benchmark of quality. Canyon Engineering undergoes stringent audits, material testing, and quality inspections to maintain its status as a trusted vendor for energy, oil & gas, and mega infrastructure firms.

Our Commitment Includes:

Full compliance with Saudi Aramco Engineering Standards (SAES)

In-house testing for yield strength, shear load, and impact resistance

Packaging and labeling in accordance with project-specific EPC requirements

By offering documented traceability and pre-approved fastener kits, Canyon minimizes delays during installation and inspection stages—critical in time-bound giga projects.

📊 Fastener Market Trends in 2025: Saudi Arabia and the GCC

The fastener market in the Gulf is projected to exceed USD 3.4 billion by 2025, with Saudi Arabia leading demand due to giga-projects and localization efforts. A 2025 report by Middle East Construction News found that:

Over 47% of EPC firms now require localized, certified fastener solutions

The use of high-tensile bolts has risen by 38% in the last 3 years

Logistics speed and certification compliance are key supplier selection criteria

This underscores the importance of players like Canyon Engineering, who combine technical depth, compliance, and rapid logistics with localized manufacturing knowledge.

🔧 How Canyon Engineering Supports Infrastructure Resilience

Canyon Engineering doesn’t just sell fasteners—it delivers solutions engineered for endurance. Here’s how:

Integrated Inventory System: 100,000+ fastener SKUs available for immediate GCC dispatch

Project-Specific Kits: Labeled, certified, and delivered according to site requirement

Advisory Services: Assisting EPCs and contractors in choosing the right fastener types for structural and environmental conditions

Environmental Resistance: Products engineered to perform under temperatures ranging from -20°C to +600°C

🏁 Conclusion: Canyon Engineering – Fastening the Future

Saudi Arabia’s transformation under Vision 2030 is a story of innovation, resilience, and scale—and Canyon Engineering is proud to be a key contributor. By providing Aramco-certified, high-tensile, and heavy-duty fastening solutions, we help secure the structural integrity of the Kingdom’s boldest ambitions.

Whether it’s a desert-spanning rail network, a high-speed logistics corridor, or a futuristic city, the future is being fastened together—bolt by bolt—with Canyon Engineering at the core.