Release Date

July 14, 2025

In the high-stakes world of engineering, procurement, and construction (EPC), success hinges not just on vision but on verification. While project blueprints may dazzle, it is certified, standard-compliant components—like fasteners—that ensure those visions are realized safely, efficiently, and sustainably.

For major infrastructure initiatives across Saudi Arabia and the GCC, fastener certification is no longer a value-add; it is a non-negotiable requirement.

And in this compliance-driven landscape, Canyon Engineering is certified to lead.

📌 Why Fastener Certification Matters in EPC Projects

Every bolt, nut, and washer used in oil refineries, desalination plants, transport terminals, or giga-projects like NEOM or the Red Sea Project plays a critical role.

These components are expected to withstand high tensile forces, corrosion, extreme temperatures, and constant vibration—often all at once.

Certified fasteners guarantee performance, safety, and traceability, significantly reducing the risk of structural failure, delays, or regulatory penalties.

In EPC contracts where timelines and liabilities are rigidly defined, using Aramco-certified fasteners in KSA or ISO-compliant bolts across the GCC helps ensure:

Faster project approvals

Lower risk of rework or non-conformance penalties

Smooth audits and material traceability

Enhanced reputation and client confidence

🔍 2025 Insight: According to the Saudi Industrial Compliance Authority, over 68% of all public infrastructure tenders now mandate ISO or Aramco-certified components—a 20% increase since 2022.

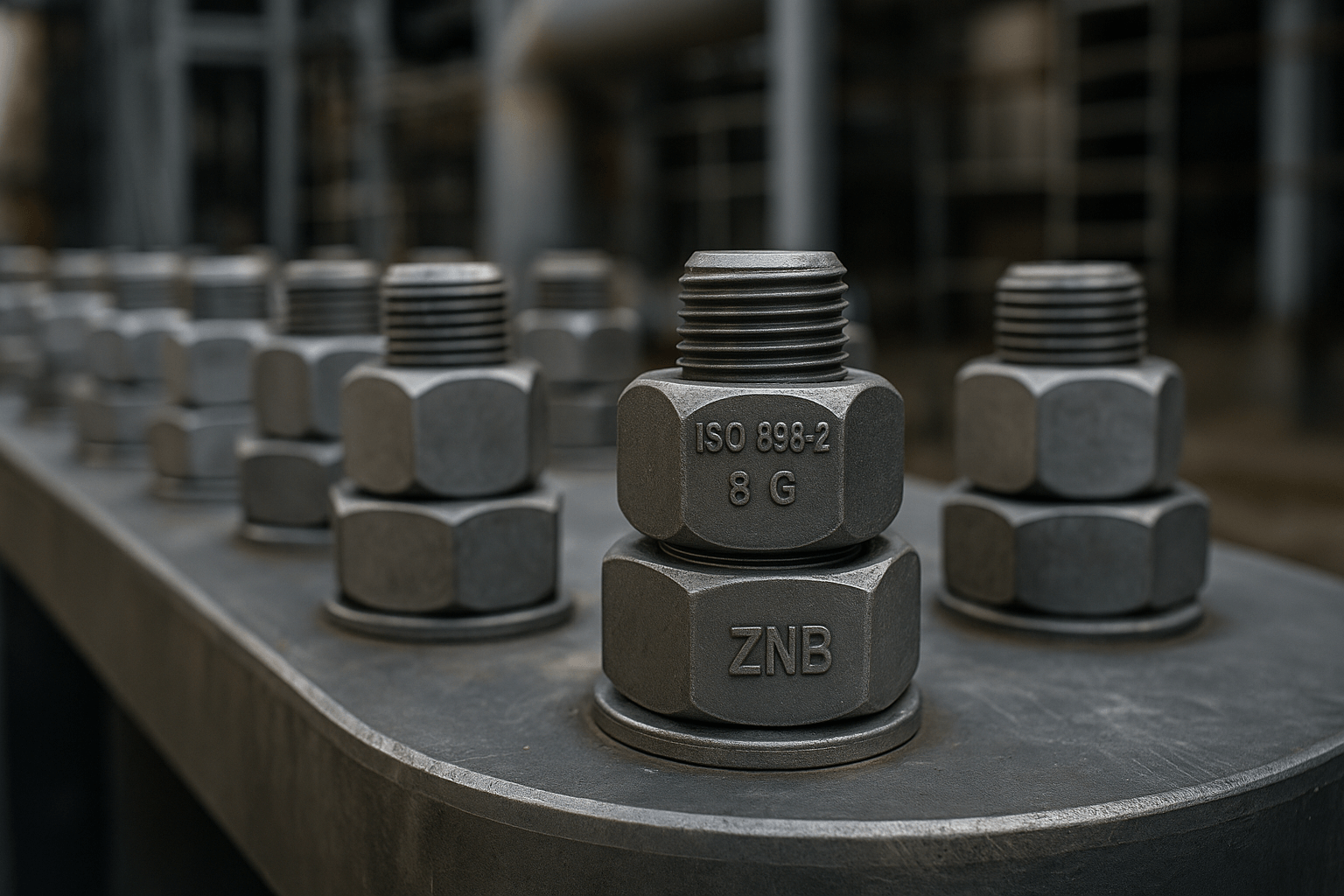

🧩 Understanding the Standards: ISO, ASTM, and Aramco

1. ISO-Compliant Bolts (GCC-Wide Standards)

The ISO 898-1 standard governs mechanical properties of fasteners made of carbon steel and alloy steel. Fasteners are classified by property classes such as 8.8, 10.9, and 12.9, denoting tensile strength and yield ratios.

✅ ISO-compliant fasteners are ideal for:

Steel structures

Bridges

Rail and tunnel infrastructure

Modular buildings and logistics terminals

2. ASTM Standards (Widely Used in Energy & Oil Sectors)

The ASTM A193 and A194 series outline specifications for alloy and stainless steel bolts used in high-temperature or high-pressure environments.

✅ These fasteners are critical in:

Petrochemical facilities

Offshore platforms

Pressure vessels and heat exchangers

3. Aramco Standards (Energy Sector’s Gold Standard)

Saudi Aramco’s vendor and materials certification requirements are among the most stringent globally. Aramco mandates not only mechanical and chemical compliance but also extensive documentation, including:

Material Test Certificates (MTCs)

Manufacturer’s Quality Assurance Plan (QAP)

Batch traceability and mill test documentation

Aramco-certified fasteners in KSA are thus synonymous with trust, durability, and audit-readiness—qualities that EPC firms cannot compromise on.

📄 The Role of MTCs and Traceability in Compliance

One of the cornerstones of fastener certification is the Material Test Certificate (MTC)—a document that certifies the chemical composition, mechanical properties, and heat-treatment record of each fastener.

At Canyon Engineering, every batch of certified fasteners is accompanied by MTCs that:

Confirm conformance to ISO/ASTM/Aramco specifications

Include heat lot numbers, tensile/yield strength, and hardness values

Are QR-coded for seamless verification and digital filing

This commitment to documentation ensures that contractors and QA officers are always inspection-ready, eliminating guesswork during third-party reviews and audits.

🔎 2025 Insight: With the rise of digital compliance platforms in the GCC, 75% of EPC firms now require QR-coded documentation and cloud-submitted MTCs.

🏗️ EPC Fastener Procurement in the Real World

Procurement teams face increasing pressure to not only source certified hardware but also to streamline delivery, avoid bottlenecks, and ensure total transparency.

Fasteners that arrive late—or without the required certification—can delay installations, risk contract penalties, or fail inspections.

Canyon Engineering’s EPC procurement model includes:

🧰 Pre-sorted kits labeled by application and project zone

📦 Certified fasteners with complete compliance docs

🔄 Real-time IMS integration for stock visibility

🛠️ Tensile-rated fasteners for specific EPC project needs

This integrated model gives EPC contractors the agility they need to keep pace with mega-project schedules.

🌍 Why Canyon Engineering Is Certified to Lead

At a time when Vision 2030 projects demand global-class execution and compliance, Canyon Engineering stands apart.

As a trusted supplier of Aramco-certified fasteners in Saudi Arabia, and a provider of ISO-compliant bolts and industrial fasteners across the GCC, Canyon delivers:

✅ Over 100,000 SKUs with certification-ready traceability

✅ Compliance with ISO, ASTM, Aramco, and SABIC standards

✅ In-house QA verification and batch testing

✅ Full support for EPC pre-qualification and documentation needs

🔚 Conclusion: Trust Is Built One Bolt at a Time

Infrastructure isn’t just about steel and concrete—it’s about the fasteners that bind everything together.

In a region where the pace of progress is accelerating, and where accountability is everything, certification isn’t optional—it’s essential.

For EPC firms building the future of Saudi Arabia and the GCC, Canyon Engineering is your certified, dependable, and documentation-ready fastener partner—because what holds your project together should never come apart.