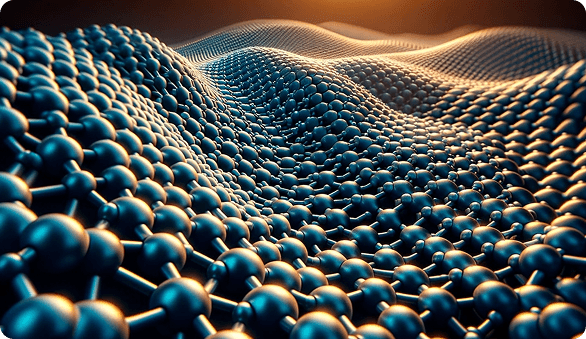

Enhanced Strength and Durability

Nano-engineered surfaces exhibit up to 300% greater resistance to wear and tear than conventional coatings

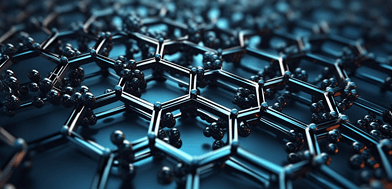

Corrosion Resistance

Up to 50% reduction in corrosion-related failures in metallic components subjected to aggressive environments