Release Date

Sep 15, 2025

Use Case 6

Industry: Defense & Heavy Engineering

Product

Protective Compounds Based on Tungsten Disulfide (WS₂) Fullerene Nanoparticles

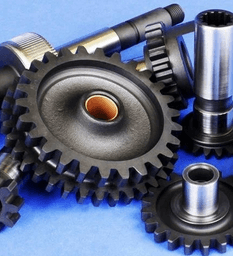

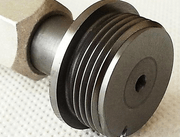

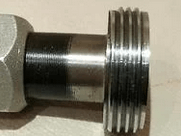

Applied as ultra-thin protective layers (5–20 μm) on gears, threads, and tooling for enhanced performance.

Challenge: In both defense and heavy engineering industries, gears, threads, and tooling are exposed to severe operating conditions, including high friction, thermal stress, and corrosive environments.

Conventional protective measures often fail to ensure the required operational longevity, leading to premature wear, frequent replacements, and costly downtime.

Problem:

Key issues identified by users and operators included:

Abrasion and corrosion reducing gear efficiency and causing failure under heavy loads.

Friction-induced wear on threads and tooling, shortening service life.

Thermal stress during prolonged operation weakening protective layers.

Lack of advanced coatings that combine low friction, abrasion resistance, and thermal durability in a single solution.

Solution

Canyon Engineering deployed compounds based on tungsten disulfide (WS₂) fullerene nanoparticles to form thin, uniform protective layers.

Before

After

Before

After

These coatings, applied at thicknesses of 5–20 μm, offer:

Extremely low friction performance, reducing wear between moving parts.

Anti-abrasive and anti-corrosive properties that extend the operational lifespan of gears and threads.

Thermo-resistant durability, ensuring consistent performance under high-heat and high-load conditions.

Scalable application to gears, all types of threaded components, and precision tooling.

Results & Benefits

Gear Protection: Significant reduction in abrasion and corrosion, resulting in longer gear life and improved transmission efficiency.

Thread Reliability: Threads of all types showed enhanced durability, maintaining integrity under repeated use.

Tooling Longevity: Protective nano-layers extended the usable life of tooling, reducing replacement costs.

Operational Efficiency: Equipment performed consistently even under extreme stress, lowering downtime and increasing readiness.

Cost Savings: Longer part lifespan and fewer replacements reduced total lifecycle costs across defense and industrial applications.

✨ Summary

By applying tungsten disulfide (WS₂) nanoparticle-based thin films, Canyon Engineering successfully addressed the challenges of gear, thread, and tooling protection in defense and heavy engineering. The solution delivered extremely low friction, anti-abrasive, anti-corrosive, and thermo-resistant protection, with thin layers (5–20 μm) enabling superior performance and cost savings.

This innovative application highlights the growing role of nanotechnology in extending the operational life of critical components.