Release Date

Sep 15, 2025

Use Case 4

Industry: Defense Industry

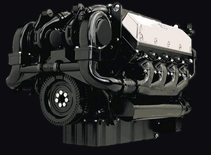

Product:

Defense & Automotive (Military Vehicles and Heavy Equipment)

Product

Tungsten Disulfide (WS₂) Fullerene Nanoparticles in Oil Suspension

Advanced lubricant additive designed to improve engine efficiency, reliability, and service life.

- Challenge: Military and heavy-duty vehicle engines operate in extreme environments where conventional oils and greases are insufficient to prevent wear, cold-start difficulties, and premature breakdown. Vehicle downtime due to engine degradation leads to higher operational costs, reduced reliability, and mission delays.

Problem:

Users faced multiple performance and maintenance challenges:

High friction and abrasion in moving engine parts reduced lifespan and increased maintenance frequency.

Cold-start difficulties in harsh environments increased operational risks and fuel consumption.

Excessive noise and vibration during operation compromised efficiency and long-term reliability.

Conventional lubricants provided limited protection, leading to accelerated wear and costly replacements.

Solution

Canyon Engineering introduced tungsten disulfide (WS₂) fullerene nanoparticles in oil suspension as an advanced additive to existing oils and greases. Leveraging their exceptionally low-friction, anti-abrasive, and self-healing properties, WS₂ nanoparticles formed a protective nanoscale layer between metal surfaces, reducing wear and enhancing lubrication under all operating conditions.

Results & Benefits

Extended Lubricant Life: WS₂ nanoparticles increased lubricant lifespan by up to 50%, reducing the frequency of oil changes.

Extended Engine Life: Engines treated with WS₂ showed significantly longer operational lifespans due to reduced wear and friction.

Improved Power & Reliability: Vehicles experienced noticeable power gains and improved reliability across extended operating cycles.

Safer Cold Starts: WS₂-enabled lubrication facilitated easier and safer cold starts, minimizing risk in harsh climates.

Lower Noise Levels: Engines operated with reduced frictional noise, improving efficiency and crew comfort.

Fuel Savings: Reduced internal friction translated into lower fuel consumption, contributing to cost savings and sustainability.

✨ Summary

By integrating tungsten disulfide (WS₂) nanoparticle additives into conventional oils and greases, Canyon Engineering delivered a next-generation solution that significantly enhanced the performance and reliability of military and heavy-duty vehicle engines.

With measurable benefits—up to 50% longer lubricant life, extended engine durability, improved cold starts, lower noise, and fuel savings—this innovation demonstrates the transformative power of nanotechnology in the defense and automotive industries..