Release Date

Sep 15, 2025

Use Case 3

Industry: Defense Industry

Product:

External and Internal Anti-Friction, Anti-Wear, and Anti-Corrosion Nanoprotection

Applied to optical and aiming device mechanisms, camouflage PUR paint (“Desert Sand”), and suppressors.

Challenge: The defense sector requires durable, reliable, and heat-resistant protective solutions that extend the operational life of critical weapon components under extreme environments. Traditional protective methods such as bluing (SORS 2348) and phosphate coating (SORS 2340) often fall short in terms of long-term corrosion resistance, especially in desert conditions where sand, heat, and humidity accelerate wear.

Problem:

Performance of LEAD BULLETS

Key operational equipment—including optical/aiming devices, camouflage-coated surfaces, and suppressors—were facing persistent issues:

Optical and aiming mechanisms suffered from friction and wear during extended use, leading to loss of accuracy.

Suppressors experienced heat-related degradation, corrosion, and reduced lifespan when exposed to high-temperature firing cycles.

Conventional coatings such as bluing and phosphate provided insufficient protection against the severe climatic and operational stressors of the desert environment.

Solution

Canyon Engineering deployed nanotechnology-based anti-friction, anti-wear, and anti-corrosion nanoprotection coatings across these components.

The advanced nanocoating solution created a uniform, heat-resistant protective barrier that penetrated microstructures, drastically enhancing performance under operational stress.

Results & Benefits

Improved anti-friction and anti-wear performance: Optical and aiming mechanisms operated with reduced resistance, extending precision accuracy and operational lifespan.

Stable heat-resistant protection: Suppressors maintained structural integrity and performance under repeated high-heat cycles.

Superior anti-corrosion protection: Corrosion resistance exceeded not only the required defense standards but also outperformed traditional methods such as bluing (SORS 2348) and phosphate coating (SORS 2340).

Operational readiness in desert conditions: Camouflage PUR paint (“Desert Sand”) retained protective properties, ensuring long-lasting durability in sand-heavy, high-temperature environments.

✨ Summary

By leveraging nanotechnology-driven coatings, Canyon Engineering successfully addressed the friction, wear, and corrosion challenges of critical defense components.

The solution delivered a measurable improvement in performance, reliability, and compliance with—and beyond—established standards, making it a proven innovation for the defense industry’s most demanding applications.

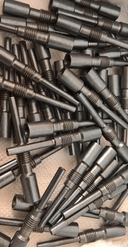

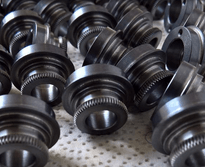

APPLICATION OF NANOTECHNOLOGY ON SPECIAL TOOLS

RESULTS

- Drawing dies for the third extraction of steel case D-52

- Punch for the third extraction of steel case D-52

- Form drills for the production of fuze body and cartridge case positions for 23 mm ammunition

- Significant increase in tool life achieved:

- Dies and punches: up to100%

- Form drills: 50%+

INVESTIGATION OF THE POSSIBILITY OF REPLACING EXISTING ORGANIC AND INORGANIC METAL PROTECTION METHODS WITH NANOMATERIALS

RESULTS

- Treated PUR paints meet the required standards SORS 1634 and SORS 1564

- Increased hardness

- Increased impact resistance by 90% (polyurethane paint)

- Requirements for resistance to aggressive environments were satisfied

- Reflection of polyurethane camouflage black paint (organic solvent-based) treated with Nanoparticles was significantly reduced, improving camouflage properties

- Research on the effect of Nanomaterials on protective properties of individual ballistic protection equipment is ongoing