Release Date

Sep 14, 2025

Use Case 1

Industry: Defense Industry

Product: Nano System Black Knight 5.8

Challenge: Extended the service life of cutting tools by 42%–120%.

Problem:

In the first application cycle, an anti-friction, anti-wear, heat- resistant, and anti-corrosion Nanotechnology-based agent was used, which significantly extended the service life of cutting tools by 42%–120%.

There was also one case where tool life was extended by up to 700%.

In the second cycle, in addition to the previously used Nano System 015, a new product, Nano System Black Knight 5.8, was tested. Unlike its predecessor, it does not require thermal treatment, which significantly simplifies and reduces the cost of the protection process.

The recorded tool life extension is currently within the same range as the first cycle, although in two cases, an increase of over 300% was observed.

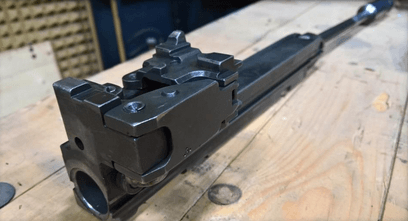

External Part – Barrel and Bolt of Browning .50 and Automatic Rifles

For heat-resistant, anti-friction, anti-wear, and anti- corrosion protection, the Nano System Black Knight 5.8 product was used.

Tests were conducted under rigorous operating conditions over a period of two years with standard maintenance.

The BROWNING .50has so far fired around 2,800 rounds(testing still in progress).

At the time of inspection, it was in excellent condition, with no visible signs of wear or corrosion.

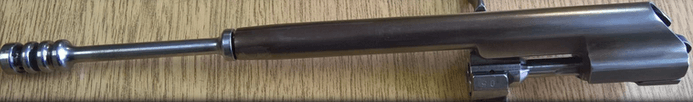

Automatic Rifles

Fired 3,000, 8,000, and 16,000 rounds.

At the time of inspection, they were in flawless condition, with no visible signs of wear or corrosion.

Bolt of Automatic Rifle

Protected with Nanotechnology:

16,000 rounds fired with standard maintenance.

Unprotected with Nanotechnology: standard maintenance only