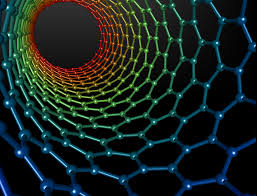

In both defense and heavy engineering industries, gears, threads, and tooling are exposed to severe operating conditions, including high friction, thermal stress, and corrosive environments. Conventional protective measures often fail to ensure the required operational longevity, leading to premature wear, frequent replacements, and costly downtime.

Month: September 2025

Use Case – How to Improve the Existing Efficiency of Nanotechnology Application in the Military Industry

Barrel wear and abrasion represent one of the most persistent problems in grenade launchers and other large-caliber weapon systems. Without advanced protective measures, barrels degrade quickly under extreme firing conditions, reducing accuracy, increasing maintenance costs, and requiring frequent replacement.

Use Case – Tungsten Disulfide Fullerene Nanoparticles in Oil Suspension

Military and heavy-duty vehicle engines operate in extreme environments where conventional oils and greases are insufficient to prevent wear, cold-start difficulties, and premature breakdown. Vehicle downtime due to engine degradation leads to higher operational costs, reduced reliability, and mission delays.

Use Case – Nano Protection for Optical and Aiming Device Mechanisms

Improved anti-friction and anti-wear characteristics of optical/aiming mechanisms

Use Case – Enhance Performance for TEST BARRELS & LEAD BULLETS

For this testing, lead bullets LRN 10.2 g, caliber 38 (.3575) were pre-treated. Bullets were coated with ultra-thin layers of fullerene nanoparticles of tungsten disulfide, without affecting the caliber.

Use Case – Defense Industry – Cutting Tools & Internal Parts and Barrels of the Browning .50 Machine Gun & Automatic Rifles

In the first application cycle, an anti-friction, anti-wear, heat- resistant, and anti-corrosion Nanotechnology-based agent was used, which significantly extended the service life of cutting tools by 42%–120%.